|

Archives |

|

Beta 1.7 |

|

Beta 1.7 |

|

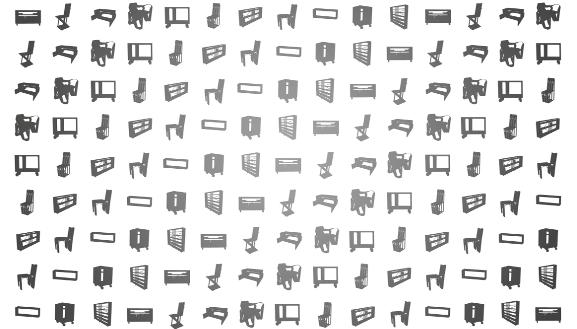

Stud Series |

|

Stud Series |

|

©2014 HEYfarmer FAQ’S |

|

Pages |

|

Stud Series |

|

| News |

|

Life (Re)cycle

On the doorstep of the Information Revolution, we need to imagine new potentials for the waste products on the Industrial Revolution. How can one produce “new” and “original” furniture for the next millennium? One way, we believe, is to discover unimagined uses for exciting technologies and common everyday materials. This is a definition of innovation: to see something old in a new light. Steel scrap is ubiquitous, finding new uses for it keeps it out of landfills and saves energy. With the “Stud Series” we have innovated a new way of recycling steel, one of the most plentiful waste products of the last century, and at the same time we have innovated a new concept in low cost and extremely practical furniture.

Light gauge steel studs, used in the construction industry as an alternative to traditional wood studs, constitute the primary material in the Series. We chose to use steel studs because they are strong, lightweight, inexpensive, durable and easy to work with. They also offer consistency and uniformity, resulting in less discarded material during manufacture.

Made primarily with steel studs, the “Stud Series” is 100% recyclable and contains a high degree of recycled steel that would otherwise be destined for landfills. The series uses simple assembly techniques and a minimal number of materials to facilitate disassembly and recycling.

Attributes

· Steel is North America’s most recycled material. · Each year, more steel is recycles than paper, aluminum, glass and plastic combined.* · Steel Studs contain 25%-100% recycled steel and are completely recyclable at the end of their useful life. · Recycling rates of steel from consumer products such as old cars, appliances, soup cans and construction materials is at an all time high. · While steel manufacturing is an energy-intensive process, the production of recycled steel consumes drastically less energy. Therefore, the original energy invested is diminished over the life of the product that can be recycled indefinitely.

Life Cycle Analysis

The International Iron and Steel institute recently announced the completion of a Global Life Cycle Inventory fpr 14 steel products. It was the largest Life Cycle Inventory ever undertaken and was developed in conformance with the ISO 14000 series of environmental standards for the Life Cycle Assessment. It is the first study in the world to ISO 1404/41 V compliant. **

The American Iron and Steel Institute also recently announced the completion of a Life Cycle Stressor Affects Assessment for galvanized steel framing.***

Past studies include a Life Cycle Analysis of the steel industry by Science Certification Systems and a study conducted by Forintek Canada Corporation and Wayne B. Trusty & Associates Limited, both in 1994.****

*The Steel Recycling Institute, www.recycle-steel.org **The Canadian Sheet Steel Building Institute, www.cssbi.ca ***American Iron and Steel Institute, AISI www.steel.org ****Environmental Building News, www.building green.com |

|

Manufacturing I

Steel scrap is all around us. Recycling 1 ton of it saves 2500 lbs. of iron ore, 1400 lbs. of coal, and 120 lbs. of limestone. Over the last 25 years the steel industry has worked with the Department of energy to develop energy-efficient manufacturing technologies, has invested $10 billion over the last decade to improve its environmental record*, and has invented more efficient recycling processers. The results include:

· 45% reduction in energy consumption per ton of steel shipped. ** · 28% reduction in CO2 emissions. · 91% less waste water emissions. · 95% of the water used for making steel is recycled. · 95% reduction in Sox emissions (responsible for acid rain). · Developments of new sheet forming the direct steel making technologies that streamline the recycling process and increase-efficiency. **

Manufacturing II

In the “Stud Series” we propose an innovative strategy for borrowing and existing technology in the form of the light gauge steel stud and applying it to the problem of furniture.

· With mass production in mid, the minor modification of existing tooling and manufacturing process saves energy over the creation of new ones. This increases the feasibility of mass production and affordability. · Steel framing is gaining popularity in the building construction industry and as a result steel studs are inexpensive and readily available. · A considerable amount of research data on the merits of steel reaming as an environmentally responsible material already exists upon which to build.

Steel studs are easy to work with using simple tools, which leads to efficient and economic fabrication. This means less energy consumed in making and greater affordability in the end product. We have developed simple yet innovative fabrication techniques that we use for forming, bending and fastening the studs. This means increased strength with fewer number of materials and fasteners.

*The Steel Alliance, www.thenewsteel.org, and Environmental Building News, www.buildinggreen.com **American Iron and Steel Institute, AISI www.steel.org |

|

Distribution

One of our design goals was to create furniture that could be fabricated efficiently and transported cheaply. Increasingly furniture is ordered via the internet and shipped to users. Minimizing the distance between the point of manufacture and the end user is an important consideration in energy conservation.

· The “Stud Series” is based on the standard unit of the steel stud. As a result the furniture is easily broken down and shipped ready to assemble in flat packaging. Its light weight and compactness saves cost and energy in transportation. · In addition taking advantage of the well established steel stud manufacturing industry could mean multiple, dispersed points of manufacture in order to minimize shipping distances.

|

|

Use

The Stud Series furniture is strong , lightweight, durable, affordable, an offers flexible configurations.

· The steel stud construction is strong and light weight which makes moving and transport much easier. · Galvanized steel is durable indoors or outdoors which adds versatility to the designs. · Using standardized and repetitive unit like the steel stud offers flexibility in design and manufacturing, i.e. a chair can easily be extended to form a bench or a shelving unit can be expanded to create a room divider.

|